Optimising Food Handling, Storage and Packaging

The MFIC includes the Produce Quality Centre (PQC) which runs the largest research facility in the UK, focused on testing strategies for handling, storage and packaging of perishable food products. The PQC facilities provide capability to control and monitor storage environments in terms of temperature and atmospheric composition, and thereby simulate both domestic and international food supply chains. The facilities comprise a suite of 10 temperature-controlled rooms with more than 70 experimental chambers each capable of independent atmospheric control and with capability to monitor the response of products to those atmospheres. The PQC works with growers, processors and technologists within Agri-tech industry both in the UK and overseas to improve long-term and short-term storage, and impact of packaging for fresh produce and other food types.

We have provided R&D support to many local companies:

“Work carried out by the team at the PQC has been invaluable to improve our long-term storage protocols for apples and pears”. Nigel Stewart AC Goathams

“The PQC are carrying out some very exciting work to improve packaging of ripe pears”. Nigel Jenner, Avalon Fresh

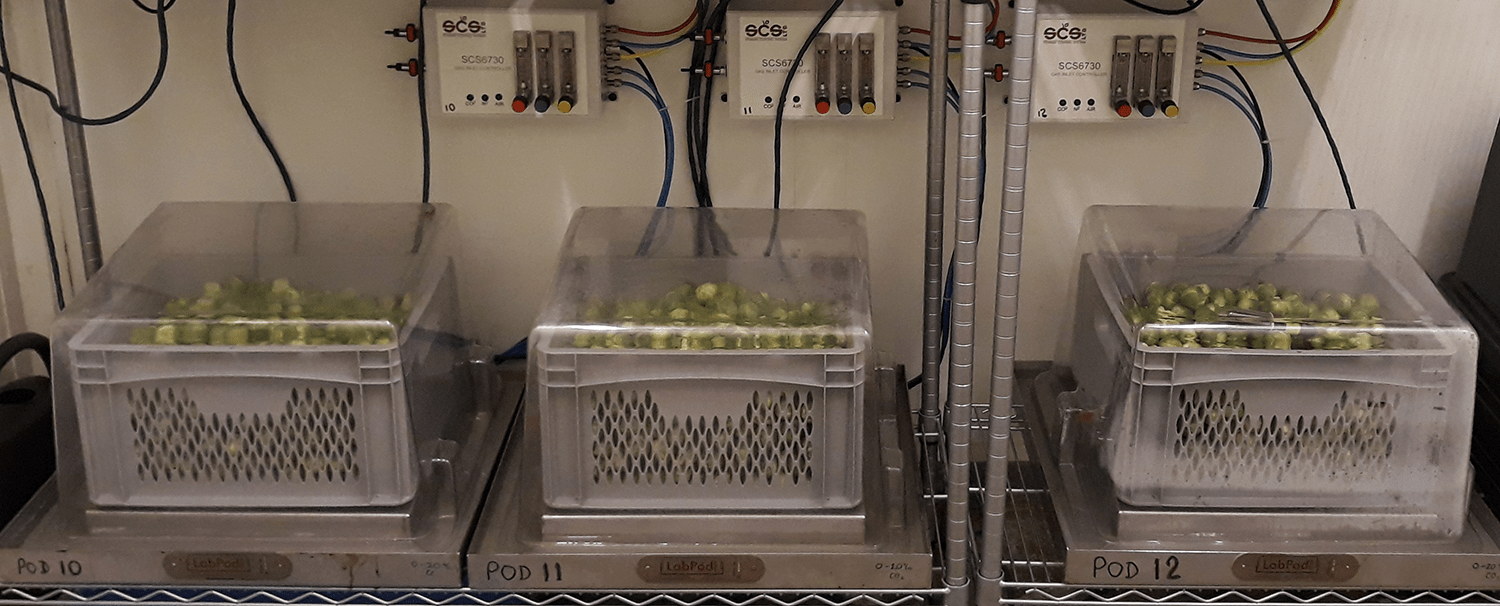

“The PQC have supported us over many years as we have developed the SafePod technology initially to improve apple storage, but now being extended to other crops including potato. Over $325 million worth of fruit is being stored with SafePod technology worldwide this season”. Jim Schaefer president SCS Ltd/Inc

“The PQC team helped us develop a programme to develop in-field cooling with the potential to extend storage life of soft fruit while also reducing labour inputs”. John Dye, JDCooling

Handling Storage and Packaging

The MFIC includes the Produce Quality Centre (PQC) focusing on the handling, storage and packaging of food, with a particular focus on fresh unprocessed fruit and vegetables and other of the most perishable food types. At the heart of the PQC is the Jim Mount Facility, the UK’s leading controlled atmosphere (CA) research storage facility. This provides capability to control and monitor storage environments and thereby simulate food supply chains providing a unique testing platform.

The PQC team includes very experienced researchers that have worked on optimising food supply chains in the UK and across the globe. In the UK, they have been central in the development of storage protocols used by UK apple pear and potato growers, and overseas they have work on in-country storage as well as transport of high value food commodities. Current projects in the UK include in-field cooling of soft fruit, decontaminating packed produce using ozone, developing storage protocols for sea-freight of perishable produce. The Centre has a particular focus on testing novel packaging solutions that are more environmentally sustainable.

Facilities

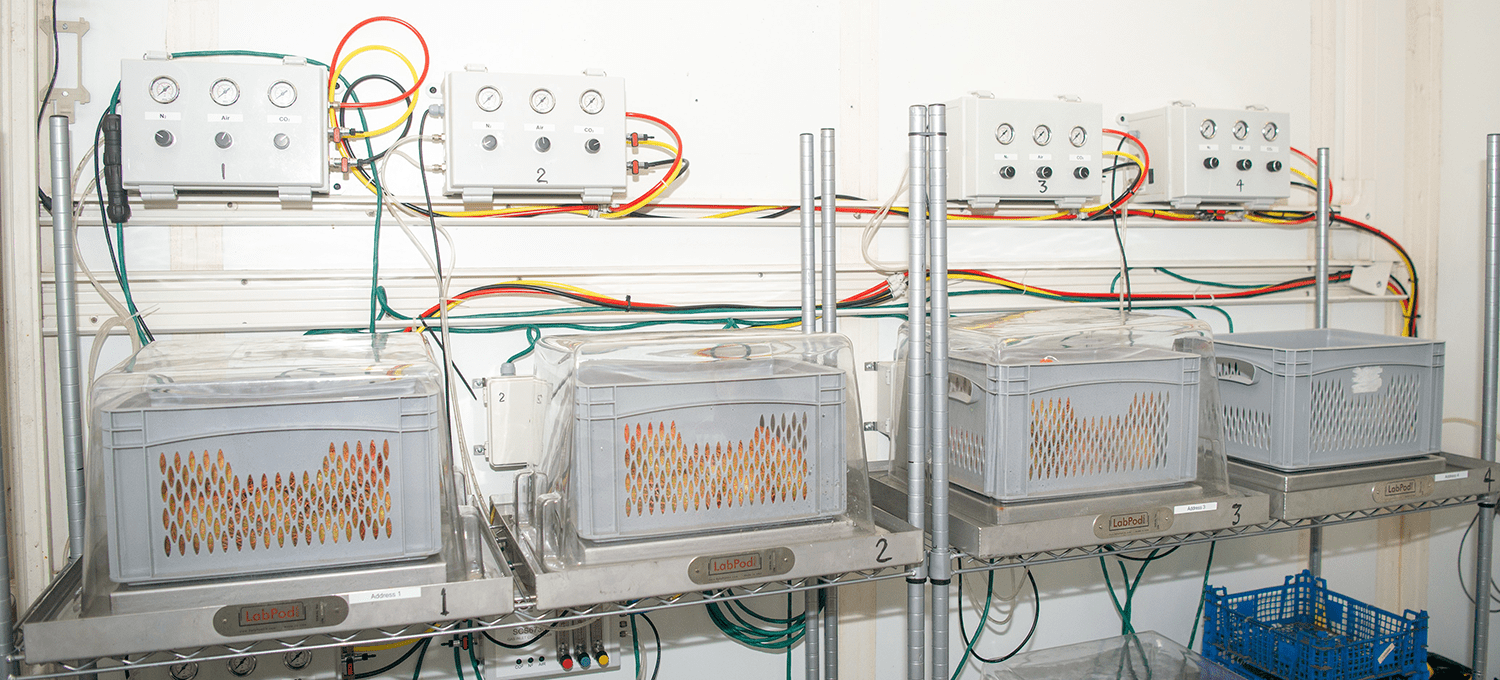

The MFIC includes the Produce Quality Centre (PQC) which runs the largest research facility in the UK, focused on testing strategies for handling, storage and packaging of perishable food products. The PQC facilities provide capability to control and monitor storage environments in terms of temperature and atmospheric composition, and thereby simulate both domestic and international food supply chains. The facilities comprise a suite of 10 temperature-controlled rooms with more than 70 experimental chambers each capable of independent atmospheric control and with capability to monitor the response of products to those atmospheres. The PQC works with growers, processors and technologists within Agri-tech industry both in the UK and overseas to improve long-term and short-term storage, and impact of packaging for fresh produce and other food types.

Summary of Facilities

- 10 adaptable controlled temperature rooms capable of control from -1°C to 30°C

- 6 large temperature-controlled rooms on the ground floor.

- 4 rooms 6 x 6 x 5.2 m height, 2 jacketed 6 x 5.3 x 4 m height.

- 2 of the non-jacketed rooms have mezzanines providing space for up to 16 CA chamber per room.

- 4 smaller rooms upstairs 3 x 3 x 2.5 m height (access by service lift).

- 6 large temperature-controlled rooms on the ground floor.

- >70 Controlled atmosphere (CA) storage chambers with automated monitoring and control in containers holding 90-500Kg of produce.

- Across the ground floor storerooms there are > 40 CA cabinets controlled centrally but with capability for each to have a different atmosphere, and each with capacity of 90 kg produce (360 L).

- LabPod chambers (SCS Ltd) each with independent CA control. >22 with capacity of 80 kg produce (430 L), 14 with capacity of 15 kg produce (41 L).

- Prototype P-Pods (SCS Ltd) dedicated to potato storage research; 4 original SafePod design, 2 adapted Mark 1 design, 4 adapted Mark 2 design.

- 3 temperature humidity programmable controlled cabinets each with capacity 1100 L

- Experimental Cooling Cell (JDCooling) for 5-10 crates, with capability for differential cooling rates to control rate of cooling with decreasing crop temperatures and prototype infra-red imaging.

- Monitoring of respiration, ethylene and ethanol production

- Quality evaluation laboratory 75 m2 including equipment for analysis of texture, colour, sugars, acids, starch assessment

- Shelf-life evaluation facilities